Coating

OPTICAL TREATMENTS

We have an extensive catalog of treatments that we can make on the most disparate materials (optical glasses, ZnSe, Si, Ge, ZnS). Some of our coatings have passed tests according to international military standards.

Gestione SILO has many years of experience, with its treatment department, in the development and production of coatings with excellent performance. The technological development given by the purchase of new machinery and equipment has allowed us to further improve our know-how.

Today, Gestione SILO boasts a wide range of coatings, for UV, Visible, NIR and IR with characteristics suitable for the most varied sectors. Among these, the military, medical, aerospace, laser and industrial sectors in general.

Among the most commonly used coatings are AR UV, AR VIS-NIR, AR IR, dichroic BeamSplitter long pass and short pass, dichroic cut on and cut off filters, metal mirrors, high reflection dielettreiciad mirrors, V coating, ITO. Most of the coatings in the catalog are tested according to the strictest international military standards. For newly developed coatings, it is possible to perform qualification tests according to the regulations required by the customer.

IBAR (Infra-red BroadBand AR Coating)

We perform this antireflection with a 3.5-5 μm spectral band on ZnSe, ZnS, Si.

Among the fields of application: night vision cameras, infrared cameras for telemetry.

Rave ≤0.7% @ 0 °

The certifications of the IBAR coating:

Cosmetics and cleaning: MIL-C675C

Severe adhesion grade 2 ISO9211

Humidity: GETS-GS-NPI

Severe abrasion grade 3 ISO9211

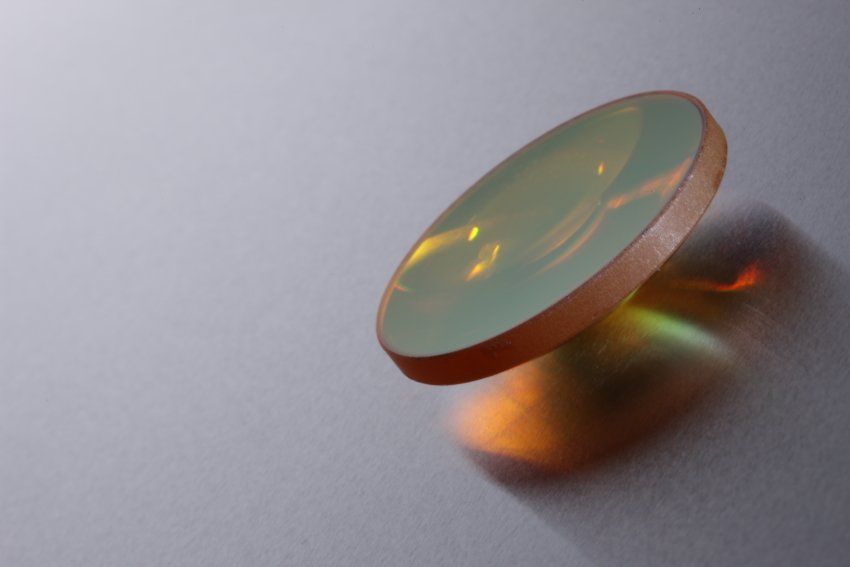

Coating for Laser CO2

AR 10.6 μ on ZnSe for CO2 laser reduces reflection to 0.5%. A visible transmission view allows alignment of the light guide, after being tested the coating has a high resistance to Laser damage. The Fields of Use range from industry to medical laser systems and laser markers.

Specifications:

R ≤0.5% A 0 °

Adhesion and abrasion according to MIL-C675

LdT:> 250 KW / Cm2 (CO2 test in CW, d = 0.16mm)

TECHNOLOGIES AVAILABLE FOR THE TREATMENT DEPARTMENT

In the course of over ten years experience, stable coating processes have been developed, tested and processed. Gestione SILO treatment department operates in a clean and air-conditioned environment; having 2 treatment plants: a Balzer and an Optotec. Here, by means of a series of customizable equipment, it is possible to process the components of various geometries with sizes from 2 mm to 1000 mm approximately.

The components to be treated are cleaned with an ultrasonic line and manual conventional cleaning according to the type of glass, so as to ensure the absence of defects on the substrate. The quality of the cosmetics of the treated elements is guaranteed by a check before and after the treatment.

DEVELOPMENT OF NEW COATING

We can develop, according to the client's request, treatments that are not already present in our coating catalog, subject to verification of feasibility by our technicians. The spectral characteristics of all our coatings are measured with a Perkin Elmer Lambda 950 spectrophotometer. We use both private and public research laboratories for the development, control of optical performance and the tests required for various types of qualification according to MIL standards and ISO.

GESTIONE SILO

Via Di Castelpulci, 14 50018 Scandicci (FI), Italia

+39 055 7221367

|

silo@silo.it

VAT Reg No. 01192850483

Legal Information

| Privacy Policy and Cookie Policy