OPTO-MEChanics

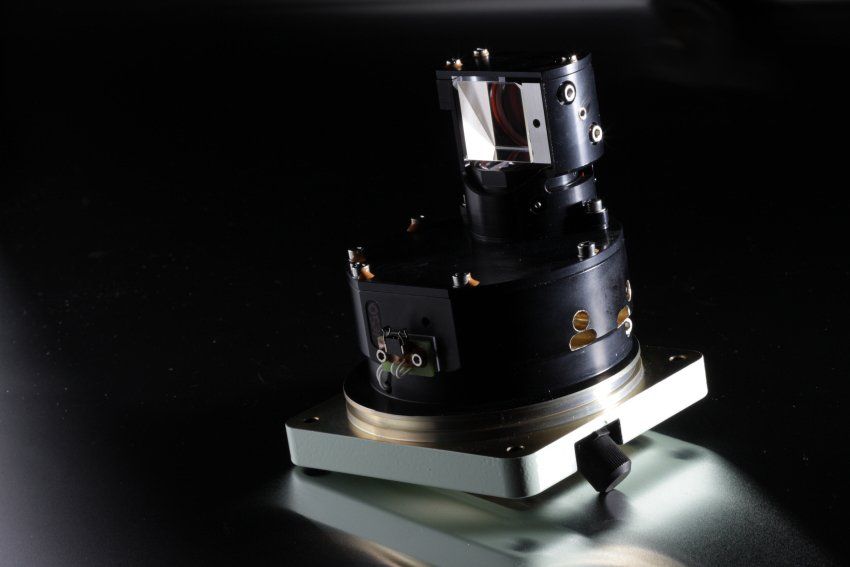

Assembly of fully custom opto-mechanical assemblies: lenses, eyepieces, relay lenses, collimators for industry, space, biomedical and military.

At our Scandicci plant, we design optical instruments such as lenses, prisms and filters that form lenses, collimators and optical assemblies of all kinds; these, in turn, form the basis for the creation of more complex instruments, such as microscopes, topographs, periscopes, binoculars, etc.

MAXIMUM ALIGNMENT PRECISION

Gestione SILO assemblies can be checked in terms of alignment accuracy, image deformation and resolution using the classic optical inspection equipment, such as collimators (up to F = 1900mm), spectrogoniometers and direct comparison systems with USAF brands resolution. Alternatively, it is possible to use Laser methods using centering devices, or interferometric methods (WFE, MTF), or custom calibration equipment. It is also possible to provide an assembly that guarantees the overpressure of the assembly itself with inert gases, for systems with use in external environments or in contact with liquids; thus garunteeing the necessary seal, verifiable by leak tests and immersion techniques.

HANDLING OF SENSITIVE COMPONENTS

Gestione SILO operators specialize in the design of optical instruments and are a point of reference for the handling of very sensitive components to the degree of cleaning, such as the optics placed on the focal planes inside the systems, and in particular the various types of lattices, of a ballistic type in the military or other fields for all other civil applications.

Gestione SILO professionals are trained to perform integrations in class 100 and also produce basic sub-assemblies for space applications using materials and processes already qualified according to ECSS standards.